|

Optical Diagnostics for Automotive R&D

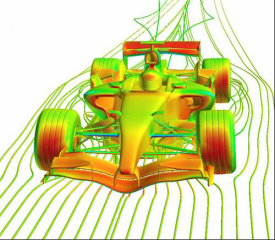

Optical diagnostic technologies such as laser imaging and fiber sensors are powerful development tools in many research laboratories of the automotive industry. They are successfully applied to measure in-cylinder processes, air flows around and inside car bodies and to study deformation and strain behavior of automotive parts under stress.

Whether your measurement focus is on engine performance, aerodynamic testing or on dynamic deformation and strain measurements - LaVision is your partner to find the best measurement solution. |

New Cell |

|

|

LaVision‘s Automotive Imaging system combines in an innovative way automotive glass inspection with image quality tests of the Advanced Driver Assistance System (ADAS).

|

|

|

Laser Imaging in EnginesMulti-functional laser imaging systems investigating all stages of internal combustion processes like fuel injection and fuel air mixing, in-cylinder flow field imaging, ignition, combustion and soot formation. |

|

EngineMaster inspexEndoscopic imaging systems for the visualization of in-cylinder processes in near production engines in combination with pressure indication. |

|

Optical Engine Indication - ICOSLaVision‘s Internal Combustion Optical Sensors (ICOS) measure crank angle resolved air/fuel ratio, exhaust gas concentration and gas temperature in near production engines. |

|

Aerodynamic Testing and Passenger ComfortLaVision‘s FlowMaster PIV systems provide most accurate flow field measurements to optimize aerodynamic efficiency, interior climate flow and aero-acoustics. |

|

Non-Destructive Deformation and Strain MeasurementsLaVision‘s StrainMaster Digital Image Correlation (DIC) systems provide contact-free deformation and strain measurements of various automotive parts such as chassis deformation or exhaust manifold expansion. In combination with flow field measurements Fluid-Structure-Interaction phenomena are analysed. |